egc

enterprises, inc.

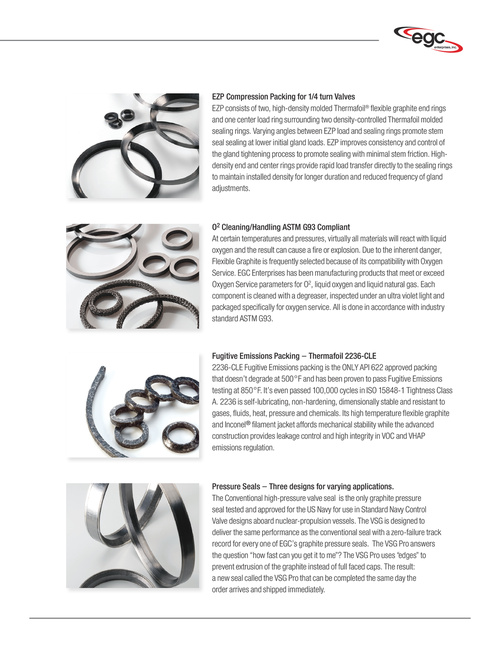

EZP Compression Packing for 1/4 turn Valves EZP consists of two, high-density molded Thermafoil®® flexible graphite end rings and one center load ring surrounding two density-controlled Thermafoil molded sealing rings. Varying angles between EZP load and sealing rings promote stem seal sealing at lower initial gland loads. EZP improves consistency and control of the gland tightening process to promote sealing with minimal stem friction. Highdensity end and center rings provide rapid load transfer directly to the sealing rings to maintain installed density for longer duration and reduced frequency of gland adjustments.

O2 Cleaning/Handling ASTM G93 Compliant At certain temperatures and pressures, virtually all materials will react with liquid oxygen and the result can cause a fire or explosion. Due to the inherent danger, Flexible Graphite is frequently selected because of its compatibility with Oxygen Service. EGC Enterprises has been manufacturing products that meet or exceed Oxygen Service parameters for O2, liquid oxygen and liquid natural gas. Each component is cleaned with a degreaser, inspected under an ultra violet light and packaged specifically for oxygen service. All is done in accordance with industry standard ASTM G93.

Fugitive Emissions Packing – Thermafoil 2236-CLE 2236-CLE Fugitive Emissions packing is the ONLY API 622 approved packing that doesn’t degrade at 500°F and has been proven to pass Fugitive Emissions testing at 850°F. It’s even passed 100,000 cycles in ISO 15848-1 Tightness Class A. 2236 is self-lubricating, non-hardening, dimensionally stable and resistant to gases, fluids, heat, pressure and chemicals. Its high temperature flexible graphite and Inconel® filament jacket affords mechanical stability while the advanced construction provides leakage control and high integrity in VOC and VHAP emissions regulation.

Pressure Seals – Three designs for varying applications. The Conventional high-pressure valve seal is the only graphite pressure seal tested and approved for the US Navy for use in Standard Navy Control Valve designs aboard nuclear-propulsion vessels. The VSG is designed to deliver the same performance as the conventional seal with a zero-failure track record for every one of EGC’s graphite pressure seals. The VSG Pro answers the question “how fast can you get it to me”? The VSG Pro uses “edges” to prevent extrusion of the graphite instead of full faced caps. The result: a new seal called the VSG Pro that can be completed the same day the order arrives and shipped immediately.